Technical information

TYPES OF TILES

All ceramic tiles produced by Zorka Keramika comply with the latest edition of the European standard EN 14411.

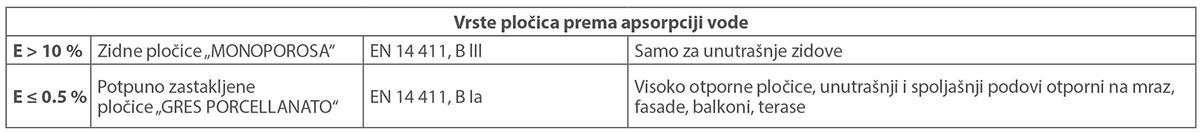

Glazed wall tiles and glazed wall decorations with water absorption E> 10% – Group B III , with parameters that comply with EN 14411. These tiles are designed for cladding internal walls at temperatures above 0 °C, as the tiles are not frost resistant.

Glazed tiles and glazed floor decorations with water absorption E< 0.5% = gres porcellanato smaltato – Group B Ia, with parameters that comply with EN 14411. These tiles are designed for interior and exterior cladding in residential buildings and in buildings of public organizations. These tiles are characterized by low water absorption, high resistance to bending, high hardness and abrasion resistance. All floor tiles produced by Zorka Keramika are gres porcellanato.

IMPORTANT TECHNICAL CHARACTERISTICS OF CERAMIC TILES

Water absorption and frost resistance

Water absorption is the most important feature when choosing the right ceramic tiles for a specific purpose, especially in wet areas environments or in zones subject to freeze/thaw cycles. In general, the lower the water absorption, the higher frost resistance, compactness and hardness of the tile.

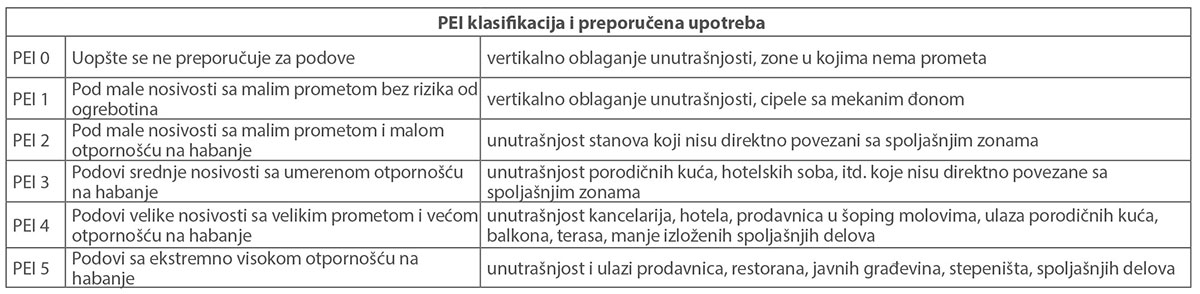

Abrasion Resistance (PEI)

The abrasion resistance of glazed tiles is one of the parameters when making a decision when choosing a suitable tile. Abrasion resistance means the tile’s resistance to mechanical wear and tear. The greater the floor’s exposure to mechanical impact and pollution from traffic, the greater resistance to abrasion is required. Very dirty particles from the streets and gardens in particular cause abrasion of the surface of the tiles, which can lead to irreversible changes in their appearance. The EN ISO 10545-7 standard in terms of abrasion classifies the resistance in classes/grades from 0 to 5. Abrasion resistance information is listed below the floor tile image.

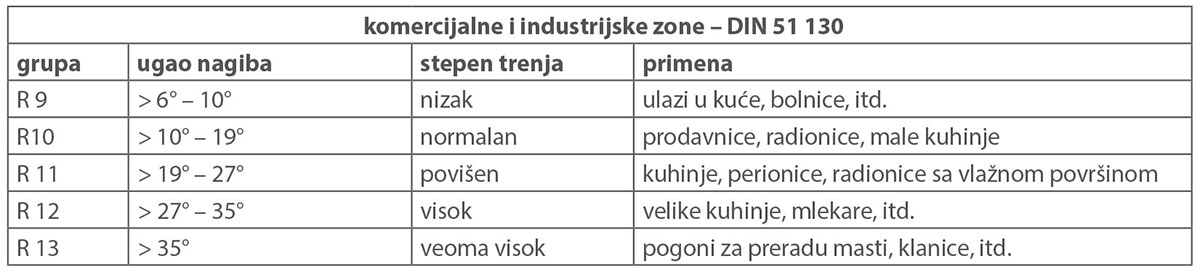

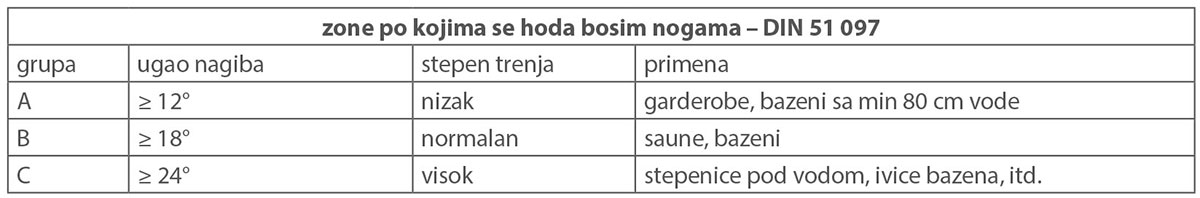

Slip resistance

In some zones, the issue of security is much more important than in other zones. It is up to those who deal with flooring products (manufacturers, architects, distributors, installers, etc.) to ensure that surfaces are fit for purpose and do not pose a safety risk to users. In the EU, there is no uniform test method and there are different requirements that define the slip-resistant surfaces of tiles in areas where people walk with shoes (DIN 51 130) or bare feet (DIN 51 097). Both tests are performed on a steep plane. For those special purposes, e.g. corridors with a high traffic of passers-by, entrances, industrial zones, kitchens, workshops, wellness centers, etc.

Zorka Keramika has developed some products that meet the aforementioned parameters as follows:

If a color is not explicitly stated, it means that all colors from that series are slip resistant. Certificate proving the stated values If a color is not explicitly stated, it means that all colors from that series are slip-resistant. You can find the certificate proving the values listed above in the Certificates chapter.

Please note that non-slip products require more demanding cleaning of the tiles.

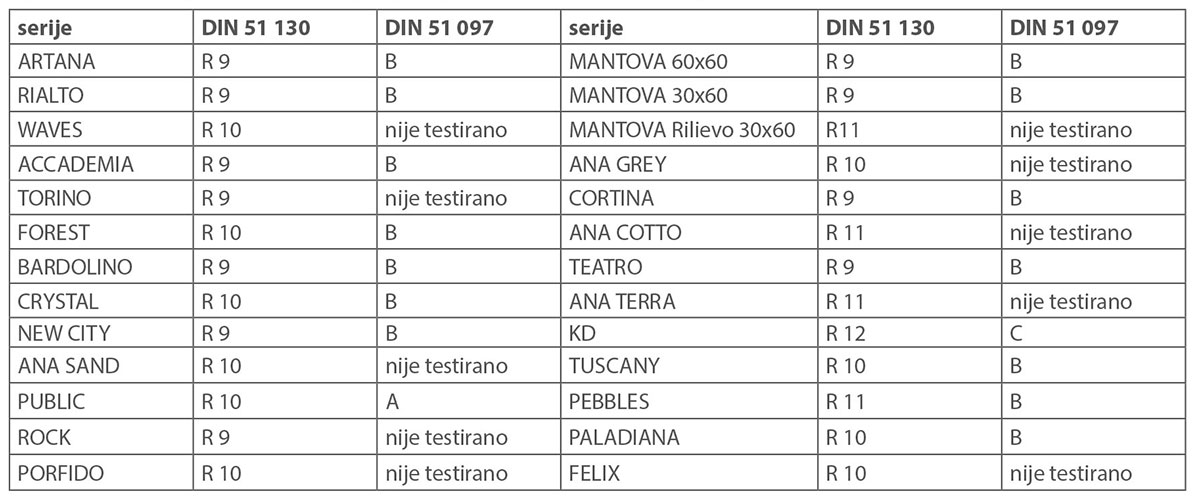

PRODUCT IDENTIFICATION ON BOXES

The tiles are packed in cardboard boxes. The first class is marked as follows:

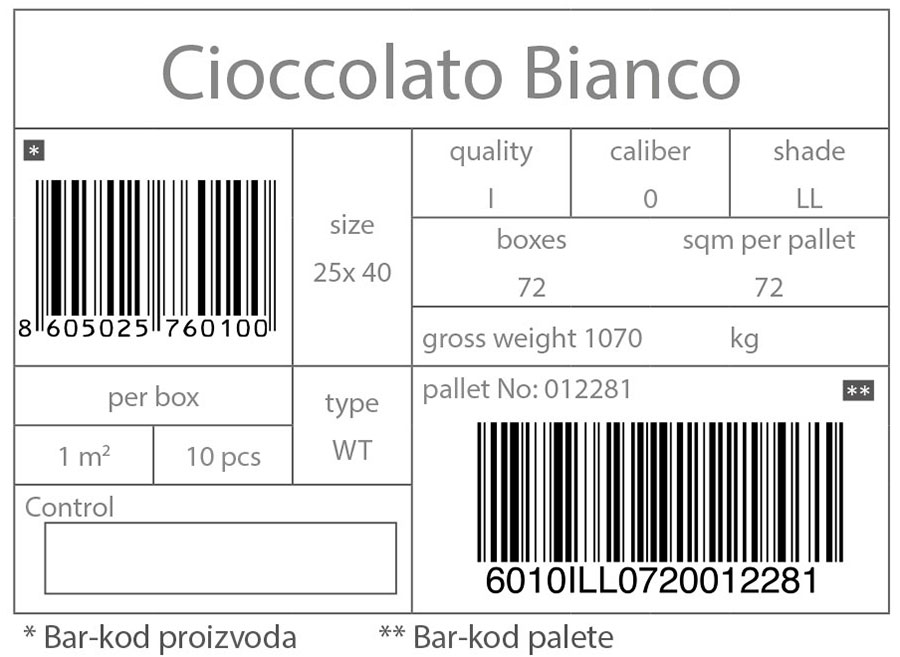

Boxes are packed on 120×80 cm pallets with the following label:

Boxes are packed on 120×80 cm pallets with the following label:

- Item Name / Design – Corresponds to the name listed in the catalog

- Class – Usually 1. class = 1, default selection = S

- Tone – It is a characteristic and typical feature of all ceramic tiles. During the firing process, several versions can appear – the color can vary in intensity, shade and texture of the surface, however, the character of the design must be preserved.

Please pay attention to this – wall tiles, floor tiles and decorations produced with modern Rotocolor technology may show slight differences in pattern, tone and intensity which are desirable and characteristic of the respective design.

To achieve the best effect, only one tone should be used in the same zone. Tone identification is generally only applied to products 1. classes - Gauge – A number that describes a group of tiles by dimension within the dimensional tolerance given by the standard. In order to achieve Caliber – A number that describes a group of tiles by dimension within the dimension tolerance given by the standard. To achieve the best effect, only one tone must be used in the same zone. Caliber identification is mainly applied to products 1. class

- Control number – A number that enables production identification. This number is important in case of any complaint.

When cladding, it is strongly recommended to use tiles of only one tone and in the same caliber for the same zone. Before tiling, it is recommended to open and mix tiles from different boxes.

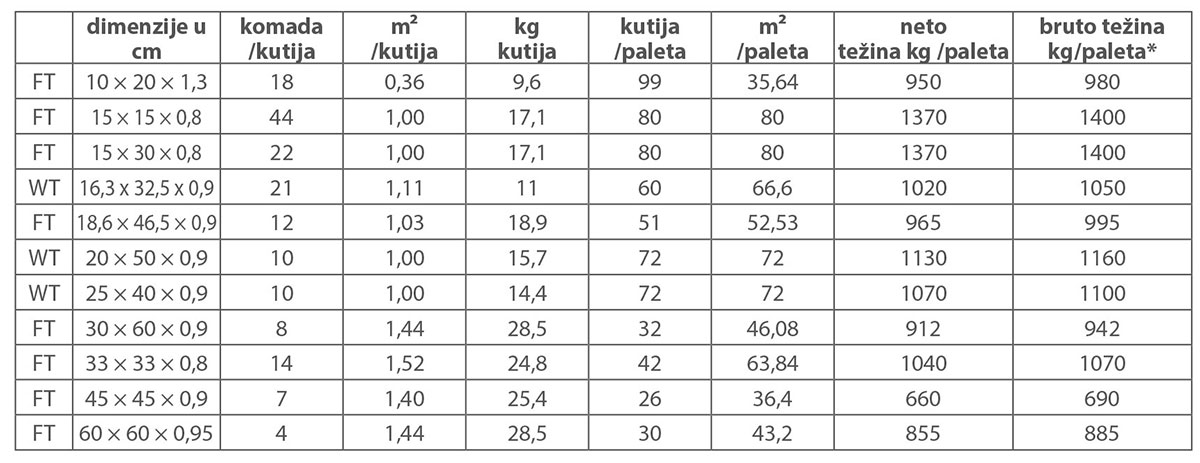

Logistics data

- incl. weight of wooden pallet / ± 5%*

- incl. the weight of the wooden pallet / ± 5% Packaging data for decorations – Listele, Inserta and other decorations – can be found directly under the picture of the decoration in the catalog.

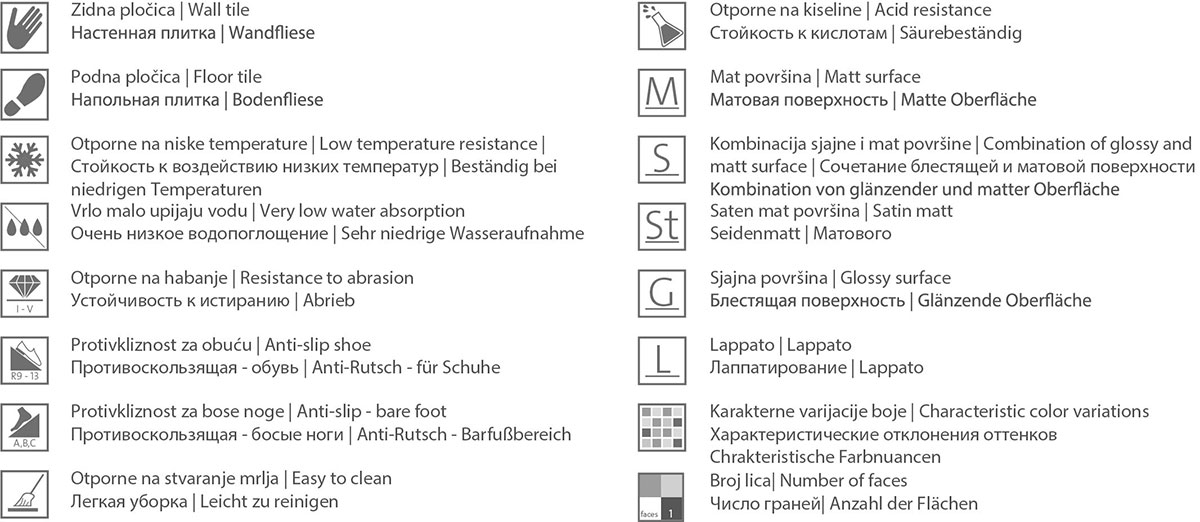

Explanation of pictograms